Mechanically held relays and contactors are often used because – Mechanically held relays and contactors are ubiquitous components in electrical systems, playing a crucial role in controlling and protecting circuits. Their reliability, durability, and cost-effectiveness make them indispensable in a wide range of applications, from motor control to power distribution.

This article delves into the intricacies of mechanically held relays and contactors, exploring their advantages, applications, design considerations, and maintenance practices. By understanding these aspects, engineers and technicians can optimize the performance and longevity of these essential electrical components.

Overview of Mechanically Held Relays and Contactors: Mechanically Held Relays And Contactors Are Often Used Because

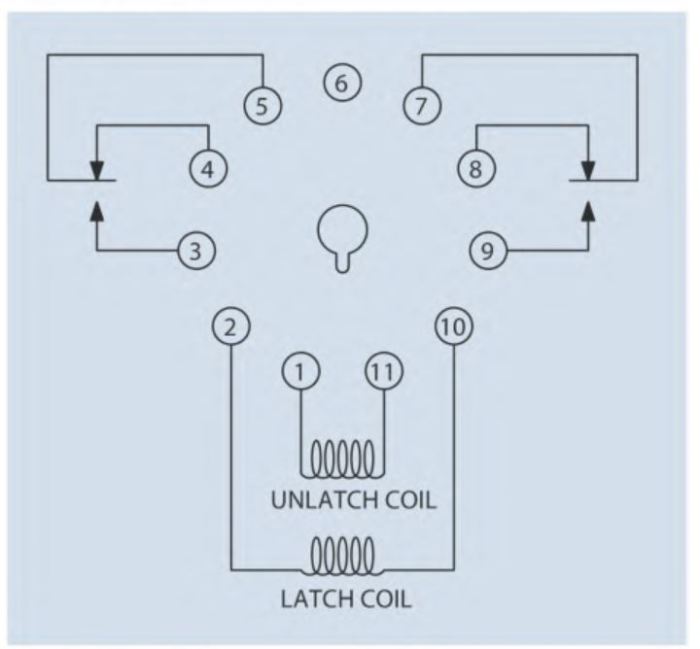

Mechanically held relays and contactors are electromechanical devices used to control electrical circuits. Relays are designed to switch low-power circuits, while contactors handle higher power loads. Both devices operate on the principle of electromagnetic induction, where an electrical current creates a magnetic field that actuates a mechanical switch.

In electrical systems, mechanically held relays and contactors play a crucial role in controlling motors, lighting, and other electrical loads. They provide isolation between control circuits and power circuits, enabling safe and efficient operation of electrical equipment.

Advantages of Using Mechanically Held Relays and Contactors

Mechanically held relays and contactors offer several advantages over other types of switching devices, including:

- High reliability and durability:These devices are built to withstand harsh operating conditions, ensuring long-term performance.

- Long lifespan:With proper maintenance, mechanically held relays and contactors can operate for millions of cycles.

- Low maintenance requirements:These devices require minimal maintenance, reducing downtime and maintenance costs.

- Cost-effectiveness:Compared to other switching technologies, mechanically held relays and contactors offer a cost-effective solution for a wide range of applications.

Applications of Mechanically Held Relays and Contactors

Mechanically held relays and contactors are widely used in various electrical systems and industrial applications, including:

- Motor control circuits:To start, stop, and reverse the direction of motors.

- Lighting systems:To control lighting circuits, including switching, dimming, and sequencing.

- Industrial machinery:To control the operation of machines, such as conveyors, pumps, and compressors.

- Power distribution systems:To isolate and protect electrical circuits, such as in substations and switchboards.

Design Considerations for Mechanically Held Relays and Contactors

When designing and selecting mechanically held relays and contactors, several factors must be considered:

Voltage and Current Ratings

The voltage and current ratings of the device must match the electrical load it will be controlling.

Contact Material and Configuration

The contact material and configuration determine the current-carrying capacity and switching characteristics of the device.

Coil Characteristics

The coil characteristics, such as voltage, resistance, and power consumption, determine the operating characteristics of the device.

Environmental Conditions

The environmental conditions, such as temperature, humidity, and vibration, must be considered to ensure proper operation.

Maintenance and Troubleshooting of Mechanically Held Relays and Contactors

Proper maintenance and troubleshooting are essential for ensuring the reliable operation of mechanically held relays and contactors:

Regular Inspections and Cleaning

Regular inspections and cleaning of the contacts and terminals help prevent contact degradation and ensure proper operation.

Contact Replacement Procedures

When contacts become worn or damaged, they must be replaced to maintain the device’s performance.

Troubleshooting Common Faults, Mechanically held relays and contactors are often used because

Common faults in mechanically held relays and contactors include contact sticking, coil burnout, and arcing. Troubleshooting these faults involves identifying the cause and implementing appropriate corrective actions.

Key Questions Answered

What are the primary advantages of mechanically held relays and contactors?

Mechanically held relays and contactors offer several advantages, including high reliability, long lifespan, low maintenance requirements, and cost-effectiveness.

In which applications are mechanically held relays and contactors commonly employed?

These components find widespread use in motor control circuits, lighting systems, industrial machinery, and power distribution systems.

What factors should be considered when designing mechanically held relays and contactors?

Design considerations include voltage and current ratings, contact material and configuration, coil characteristics, and environmental conditions.